Forming Design Style Cabinet

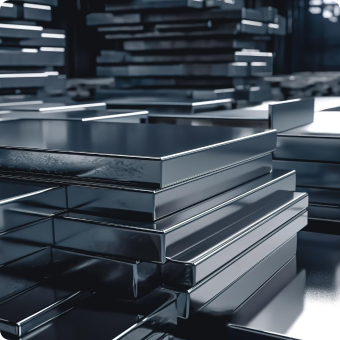

The key points of the design of the forming process for cold-rolled metal steel sheets are as follows:

Material Selection

Material Type: Choose the appropriate material based on the application, such as low-carbon steel or stainless steel.

Thickness: Select the appropriate thickness according to design requirements to ensure strength and formability.

Mold Design

Mold Material: Use wear-resistant and high-hardness materials, such as tool steel.

Mold Structure: Ensure a reasonable structure to avoid stress concentration and extend mold life.

Forming Process Parameters

Pressure Control: Adjust the pressure based on material thickness and shape to avoid deformation or cracking.

Speed Control: Control the forming speed appropriately to ensure quality.

Temperature Control: Cold-rolled steel sheets are typically formed at room temperature, but heating may be applied if necessary.

Quality Control

Dimensional Accuracy: Strictly control dimensions to ensure they meet design requirements.

Surface Quality: Inspect the surface to avoid defects such as scratches or cracks.

Equipment Maintenance

Regular Inspection: Perform regular maintenance to ensure proper equipment operation.

Mold Maintenance: Regularly maintain molds to extend their service life.

Safety Measures

Operational Safety: Ensure operators follow safety procedures.

Equipment Safety: Ensure safety devices are functional to prevent accidents

Environmental Protection and Energy Efficiency

Environmental Protection: Reduce waste and pollutant emissions.

Energy Efficiency: Optimize the process to reduce energy consumption.

* Summary

the design of the forming process for cold-rolled metal steel sheets requires comprehensive consideration of factors such as material, mold, process parameters, lubrication, quality control, equipment maintenance, safety, and environmental protection to ensure product quality and production efficiency.